Ducati Scrambler 800 - Service manual > Closing the crankcase

Ducati Scrambler 800 - Service manual > Closing the crankcase

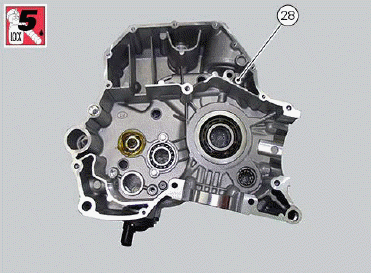

If previously removed, apply specified threadlocker to dowel (28) and tighten to a torque of 15 Nm (Min.

13 Nm - Max. 17 Nm).

After tightening, remove the excess of threadlocker.

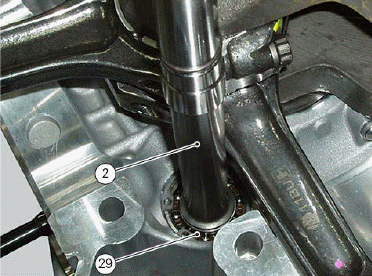

Install the timing layshaft (2) in the roller bearing (29) on the clutch-side crankcase half.

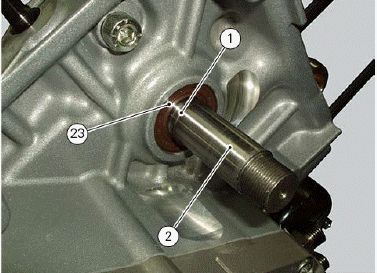

To avoid damaging the sealing ring (23) on the timing layshaft, protect the threaded end of the shaft with the special protective cap part no. 88700.5749.

Dampen sealing ring (23) with alcohol and fit it on the timing layshaft. Push seal until it contacts the roller bearing (29).

Fit the snap ring (1) in the groove on the shaft and remove the protective cap.

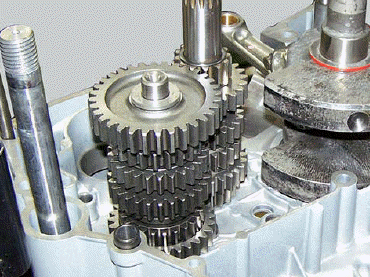

Note When refitting used components, before installing the gearbox assembly in the crankcase half, make sure that the inner races of the gearbox shaft end bearings are fitted into the correct bearings and have not been left on the shafts.

Match gearbox shafts, fit the calculated shims and fit them to the clutch-side crankcase half.

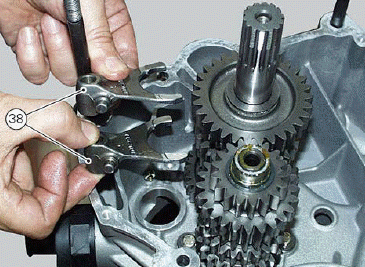

Insert the forks of 1st - 4th and 2nd - 3rd speed (38) inside the sliding grooves of the secondary shaft driven gears.

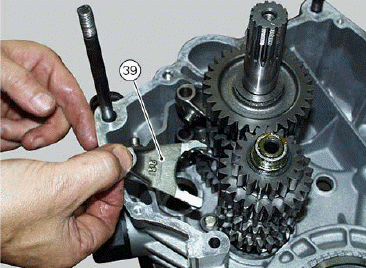

Insert the fork of 5th - 6th speed (39) inside the primary shaft driven gear.

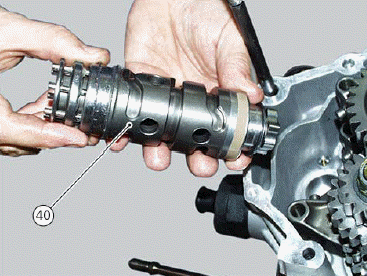

Fit the fork selector drum (40) with the calculated shims on crankcase half.

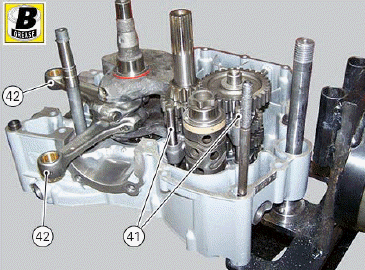

Install pins (41) in the previously installed forks.

Fit crankshaft with the specially calculated shims inside clutch side crankcase half bearing, positioning connecting rods (42) in the relevant seats of the cylinders.

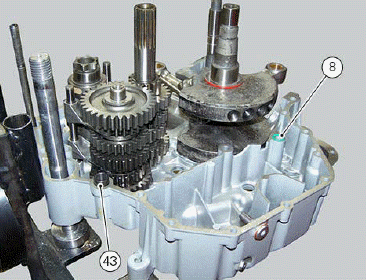

Check that the two centring bushes (43) are correctly fitted.

After having duly greased it to hold it in position, install the O-ring (8) on the oil channel, between the two crankcase halves.

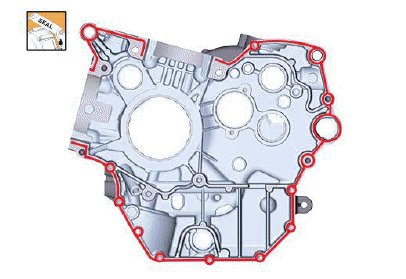

Apply an even and continuous bead of DUCATI sealing compound to the mating surface of the crankcase halves, going around all the holes as shown in the figure.

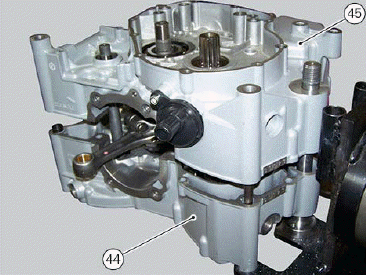

Bring the crankcase halves (44) and (45) together, tapping with a rubber mallet in the area of the shafts if necessary.

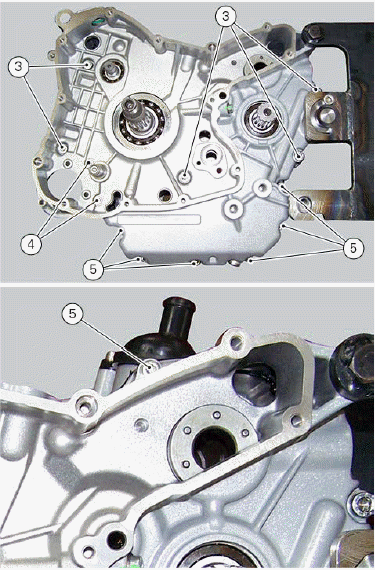

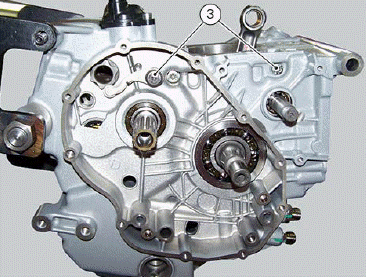

Start screws (3), (4) and (5) on the generator-side crankcase half, paying attention to the different lengths.

Start and progressively drive fully home the jointing screws starting with those with a larger diameter (M8).

Install two M8 screws (3) on the clutch side crankcase half.

Tighten all screws to the indicated torque:

- screws (8) first to a snug torque of 19 Nm (Min. 17 Nm - Max. 21 Nm), then to a tightening torque of 25 Nm (Min. 22 Nm - Max. 28 Nm);

- screws (4) and (5) to a torque of 10 Nm (Min. 9 Nm - Max. 11 Nm).

Refit the complete cylinder/piston assembly (Refitting the cylinder/piston assembly).

Refit the complete cylinder head assembly (Refitting the cylinder heads).

Refit the flywheel/generator assembly (Refitting the flywheel/generator assembly).

Refit the oil pump (Refitting the oil pump).

Refit the engine in the frame (Refitting the engine).

See also:

Ducati Scrambler 800 - Service manual > Shimming the shafts

Ducati Scrambler 800 - Service manual > Shimming the shafts

Before assembling the crankcase halves, it is necessary to calculate the shim that determines the end float of the crankshaft and of the gearbox shafts. Calculate the shimming following the procedures described below.

Ducati Scrambler

Ducati Scrambler Fantic Caballero 500

Fantic Caballero 500 Indian FTR 1200

Indian FTR 1200 Moto Guzzi V85 TT

Moto Guzzi V85 TT Royal Enfield Bullet Trials Works Replica

Royal Enfield Bullet Trials Works Replica Triumph Scrambler 1200 XE

Triumph Scrambler 1200 XE Triumph Street Scrambler

Triumph Street Scrambler Yamaha XSR700

Yamaha XSR700 Ducati Scrambler 800

Ducati Scrambler 800 Moto Guzzi V85 TT

Moto Guzzi V85 TT Triumph Scrambler 1200 XC

Triumph Scrambler 1200 XC