Triumph Scrambler 1200 XC - Service manual > Crankcase

Triumph Scrambler 1200 XC - Service manual > Crankcase

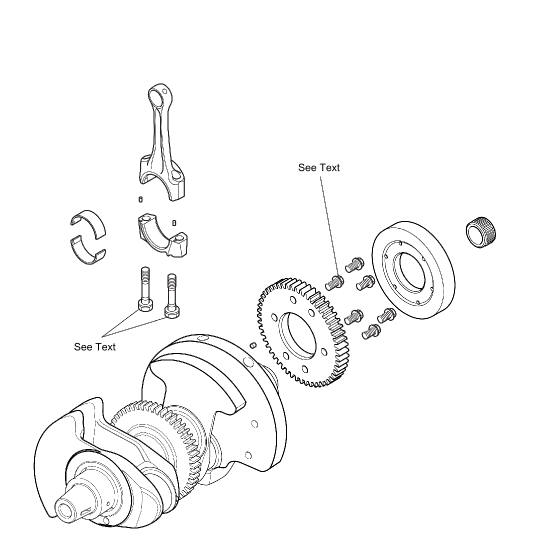

Exploded View - Crankshaft and Connecting Rod

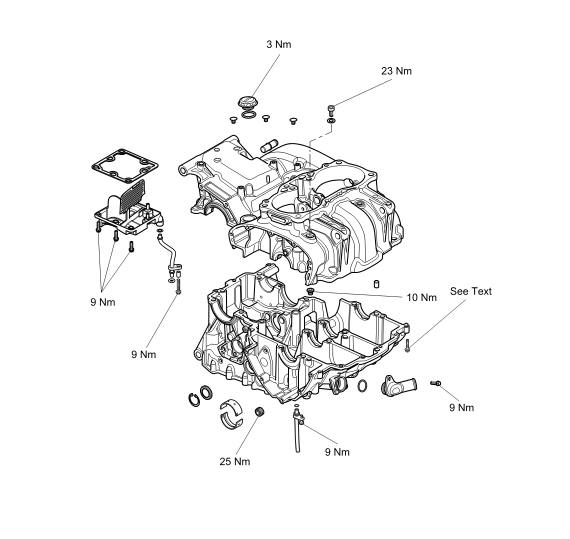

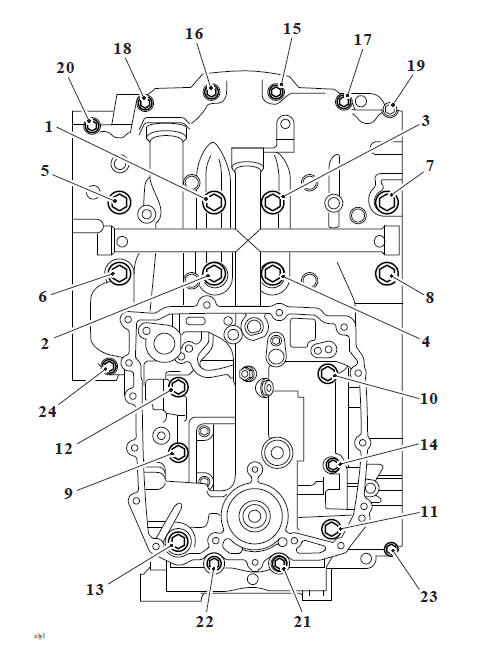

Exploded View - Crankcase

Crankcase - Disassembly

WARNING

Before starting work, ensure the motorcycle is stabilised and adequately supported. This will help prevent it from falling and causing injury to the operator or damage to the motorcycle.

Perform the following operations:

- Seat - Removal

- Battery - Removal

- Fuel Tank - Removal

- Engine - Removal

- Camshaft Cover - Removal

- Sump - Removal

- Alternator Rotor - Removal

Note

To allow correct fitment of T3880039 - Idler Gear Timing Pin the engine may require rotating up to seven times.

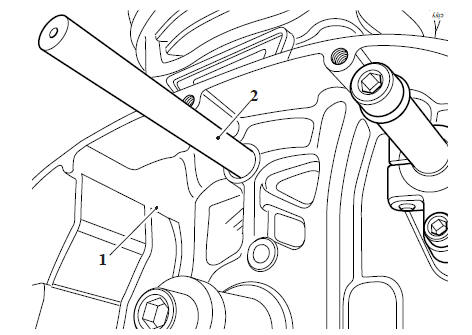

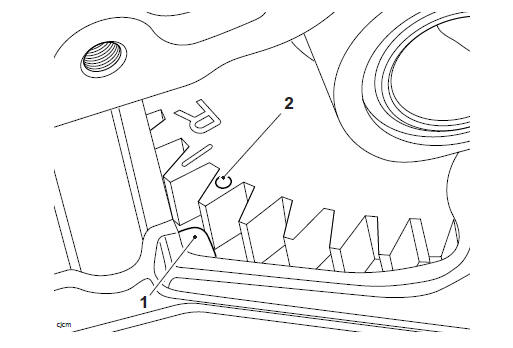

1. Align the timing holes in the crankcase and camshaft idler gear. Lock in position using T3880039 - Idler Gear Timing Pin.

- Crankcase

- T3880039 - Idler Gear Timing Pin

2. Remove the oil and water pump (see Oil and Water Pump - Removal).

3. Release the fixing and remove the coolant drain tube, discard the fixing and the O-ring.

- Coolant drain tube

- Fixing

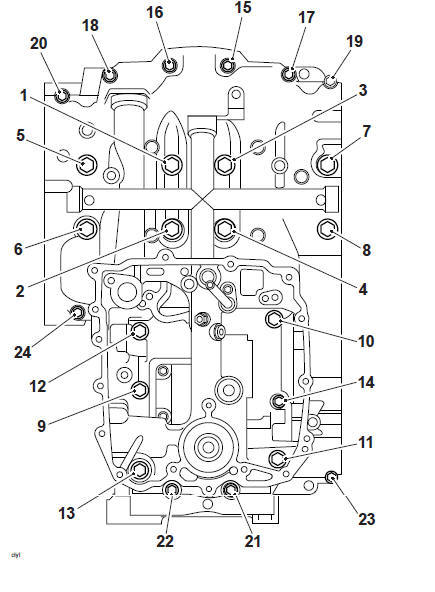

4. Release the lower crankcase fixings noting their positions in the sequence shown below.

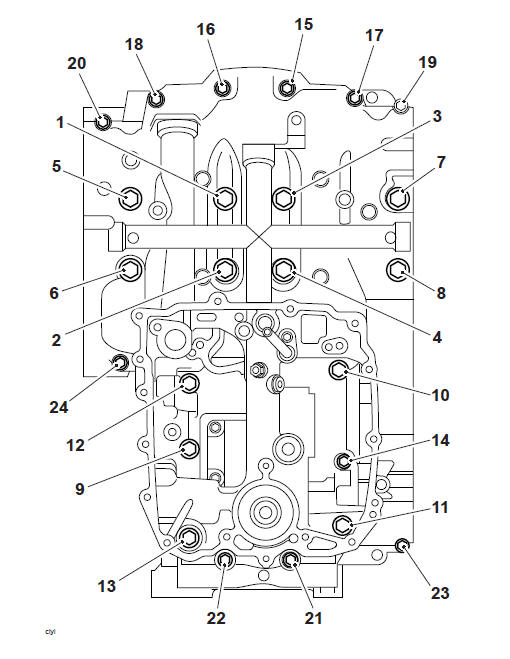

Crankcase Fixing Release Sequence

CAUTION

Do not use levers to separate the upper and lower sections of the crankcase as damage to the crankcases could result.

Note

Always check that all fixings have been released before attempting to separate the crankcases.

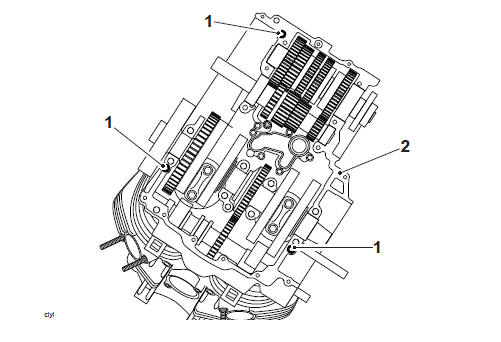

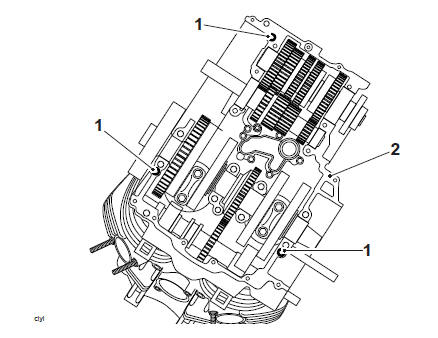

5. Separate the lower crankcase from the upper crankcase noting the position of the three location dowels.

- Dowels

- Upper crankcase

Perform the following operations:

- Front Balancer Shaft - Removal

- Rear Balancer Shaft - Removal

- Crankshaft - Removal

- Selector Forks and Drum - Removal

- Coolant Manifold - Removal

- Breather Plate - Removal

Crankcase - Assembly

1. Use high flashpoint solvent to clean the crankcase mating faces. Wipe the surfaces clean with a lint-free cloth.

2. Position the transmission shafts and the selector drum in the 2. neutral position.

3. Ensure that the three dowels are located in position in the upper crankcase.

- Dowels

- Upper crankcase

4. Install and lubricate the crankshaft main bearing shells with clean engine oil (see page Crankshaft Main Bearing/Journal Checking, Measuring and Bearing Selection before proceeding).

5. Install and lubricate the front balancer shaft with clean engine oil (see Front Balancer Shaft - Installation).

6. Install and lubricate the rear balancer shaft with clean engine oil (see Rear Balancer Shaft - Installation).

7. Lubricate the crankshaft journals with clean engine oil.

8. Apply a 2 mm (+/-0.5 mm) bead of silicone sealant to the lower crankcase mating faces, (during manufacture, ThreeBond 1216E is used).

Sealer Areas

CAUTION

Do not use excessive amounts of sealer. The extra sealer may become dislodged and could block the oil passages in the crankcases, causing severe engine damage.

9. Position the lower crankcase to the upper crankcase. An assistant may be required to support the crankcase during alignment.

Note

- The rear balancer shaft will rotate one tooth when the upper and lower crankcase are joined.

10. To check that the balancer shaft is correctly timed to the crankshaft proceed as follows:

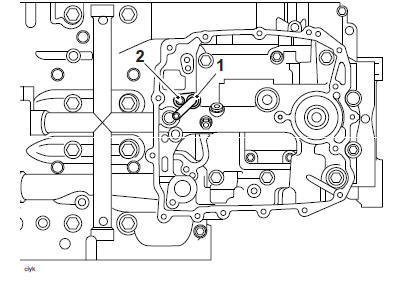

11. Check that the dot mark on the rear balancer shaft gear is aligned with the tab on the crankcase, as shown below.

- Lower crankcase identification mark

- Rear balancer shaft dot mark

12. Locate the fixings into their respective positions in the lower crankcase as noted during removal and hand tighten.

13. Tighten the crankcase fixings as follows:

Note

The crankcase fixings are tightened in stages.

CAUTION

Failure to follow the correct tightening sequence may result in permanent crankcase damage.

Stage 1 - All Fixings

14. In the sequence shown below:

- Tighten all of the crankcase fixings to 10 Nm.

All Fixings Tightening Sequence

Stage 2

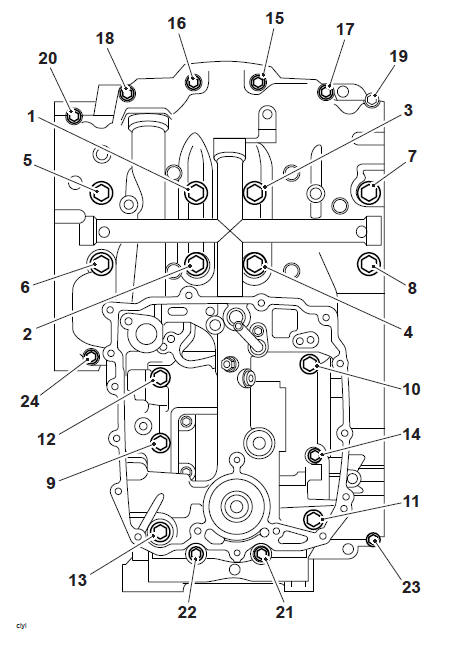

15. In the sequence shown below:

- Loosen fixings 1 to 8. through 140º, using T3880105 - Torque Angle Gauge or similar to measure the torque-angle.

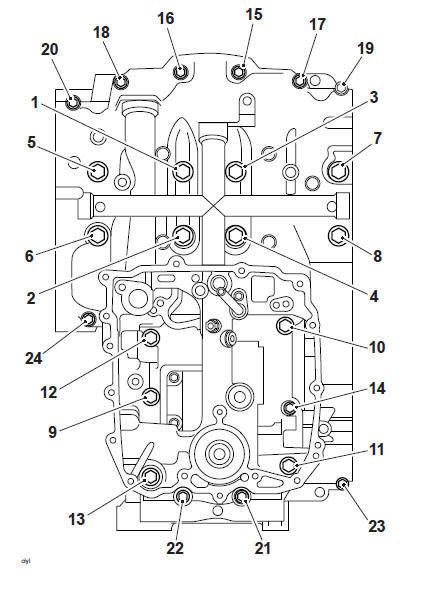

Fixings 1 to 8 Loosening Sequence

Stage 3

16. In the sequence shown below:

- Tighten fixings 1 to 8 to 11 Nm.

Fixings 1 to 8 Tightening Sequence

17. In the sequence shown below:

- Tighten fixings 1 to 8 through a further 75º using T3880105 - Torque Angle Gauge or similar to measure the torque-angle.

Fixings 1 to 8 Tightening Sequence

Stage 4

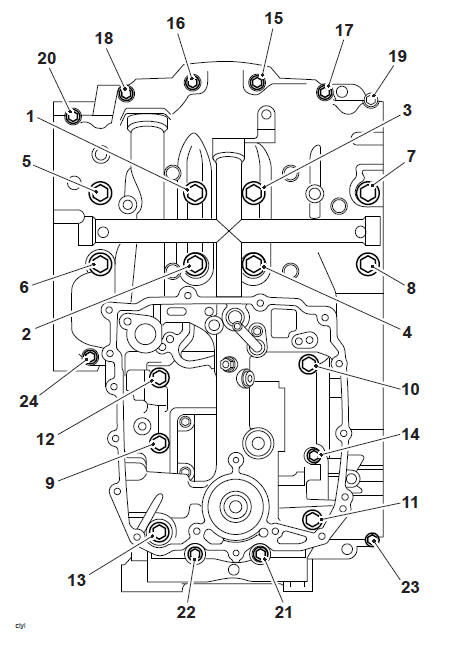

18. In the sequence shown below:

- Tighten fixings 9 to 13 to 32 Nm.

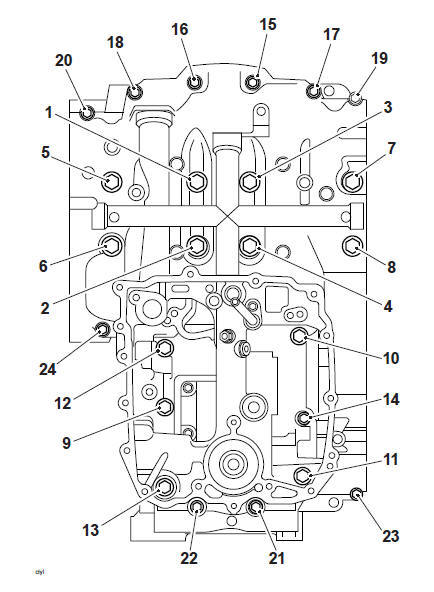

Fixings 9 to 13 Tightening Sequence

Stage 5

19. In the sequence shown below:

- Tighten fixings 14 to 24 to 12 Nm.

Fixings 14 to 24 Tightening Sequence

Note

- Prior to fitting an O-ring coat the surfaces with a commercially available petroleum jelly

20. Refit the breather drain tube, fit a new O-ring, tighten the new fixing to 9 Nm.

- Breather drain tube

- Fixing

Perform the following operations:

- Oil and Water Pump - Installation

- Sump - Installation

- Alternator Rotor - Installation

- Clutch - Installation

- Gear Position Sensor - Installation

- Engine - Installation

- Fuel Tank - Installation

- Battery - Installation

- Seat - Installation

Crankshaft - Removal

WARNING

Before starting work, ensure the motorcycle is stabilised and adequately supported. This will help prevent it from falling and causing injury to the operator or damage to the motorcycle.

Perform the following operations:

- Seat - Removal

- Battery - Removal

- Fuel Tank - Removal

- Engine - Removal

- Crankcase - Disassembly

- Connecting Rods - Removal

Note

Support the connecting rods during crankshaft removal to prevent damage to the rods, liners and upper crankcase.

1. Remove the crankshaft from the upper crankcase.

Crankshaft - Installation

CAUTION

Always check the main bearing journal clearance (see Crankshaft Main Bearing/Journal Checking, Measuring and Bearing Selection), before final assembly of the crankshaft. Failure to correctly select crankshaft bearings will result in severe engine damage.

1. Select and fit new main and big end bearing shells using the selection processes detailed in Crankshaft Main Bearing/Journal Checking, Measuring and Bearing Selection.

2. Lubricate all of the bearings with clean engine oil.

3. Ensure that the crankshaft is clean, and that the oil ways within the crankshaft are clean, free from blockages and debris.

CAUTION

The crankshaft to idler gear timing will be lost when the crankshaft is removed. Do not refit the crankshaft without first setting the crankshaft to idler gear timing.

Incorrect idler gear timing will result in incorrect camshaft timing. Rotating or attempting to start an engine with incorrectly adjusted camshaft timing will result in severe engine damage.

4. Install the crankshaft to the upper crankcase, ensuring the crankshaft drive gear is correctly timed to the balancer shafts and idler gear (see Front Balancer Shaft - Installation).

5. Align the connecting rod big ends to the crankshaft pins.

6. Fit, and in the correct sequence, tighten the big end caps. (see Connecting Rod - Installation).

7. Assemble the crankcases (see Crankcase - Assembly).

Perform the following operations:

- Barrels - Installation

- Cylinder Head - Installation

- Engine - Installation

- Fuel Tank - Installation

- Battery - Installation

- Seat - Installation

- Start the engine and ensure that the low oil pressure warning light goes out shortly after starting.

- Stop the engine and check the engine oil level. Adjust if necessary (see Engine Oil - Level Inspection).

See also:

Triumph Scrambler 1200 XC - Service manual > Connecting Rods

Triumph Scrambler 1200 XC - Service manual > Connecting Rods

Connecting Rods - Removal Perform the following operations: Fuel Tank - Installation Battery - Installation Seat - Installation

Ducati Scrambler

Ducati Scrambler Fantic Caballero 500

Fantic Caballero 500 Indian FTR 1200

Indian FTR 1200 Moto Guzzi V85 TT

Moto Guzzi V85 TT Royal Enfield Bullet Trials Works Replica

Royal Enfield Bullet Trials Works Replica Triumph Scrambler 1200 XE

Triumph Scrambler 1200 XE Triumph Street Scrambler

Triumph Street Scrambler Yamaha XSR700

Yamaha XSR700 Ducati Scrambler 800

Ducati Scrambler 800 Moto Guzzi V85 TT

Moto Guzzi V85 TT Triumph Scrambler 1200 XC

Triumph Scrambler 1200 XC