Triumph Scrambler 1200 XC - Service manual > Immobiliser and Keyless Ignition System

Triumph Scrambler 1200 XC - Service manual > Immobiliser and Keyless Ignition System

System Description

This model is fitted with an electronic immobiliser and keyless ignition system to help protect it against theft. The immobiliser and keyless ignition system is incorporated in the keyless ECM. The keyless ECM has to be paired with the engine ECM and the ignition keys which each contain a transponder chip. If all the components are correctly paired, the immobiliser will allow the engine to start. These components can only be paired using the Triumph diagnostic tool..

In addition, the system has an on-board diagnostic function. This ensures that, should a malfunction occur in the immobiliser system, a malfunction code is stored in the keyless ECM memory. This stored data can then be recovered using the Triumph diagnostic tool (see System Diagnostics).

System Components and Operation

- Transponder chip - situated inside the ignition key. The chip is activated when requested by the keyless ECM, providing the key is in range of the LF antenna (within one meter/three feet for smart keys, within 50 mm for passive keys).

- Low Frequency (LF) Antenna - there are two LF Antenna on this model. One is situated on the base of the storage box under the rider's seat. The second is inside the headlight bowl. The transponder chip in the ignition key is activated when it is in range of the LF antenna. The signal from the chip is interpreted by the keyless ECM.

- Keyless ECM - situated at the rear of the airbox. This control module communicates with the transponder chip in the key via the LF antenna, and with the engine ECM. The keyless ECM will only allow the motorcycle's electronic systems to turn on and the engine to start if a matching signal is received.

- Alarm/immobiliser warning indicator light - situated in the instrument

pack. The

light will flash on and off for 24 hours to show that the engine immobiliser

is on.

When the ignition switch is turned to the ON position the immobiliser and the indicator light will be off. If the indicator light remains on it indicates that the immobiliser has a malfunction that requires investigation. If an accessory alarm is fitted, the immobiliser indicator light will only illuminate when the conditions described in the accessory alarm instructions are met.

Keys

When the motorcycle is delivered from the factory it is supplied with two standard keys and one smart key.

Note

- An additional smart key can be purchased from your Triumph dealer. However, only three keys can be programmed to the motorcycle. This can be any combination of smart keys and standard keys.

- A previously paired key must be present when pairing a new key.

- Ensure all keys to be paired are present before starting the key pairing process.

Keys can be deleted or added to the immobiliser system using the Triumph diagnostic tool.

To ensure the immobiliser system functions correctly note the following:

- Do not put any magnetic materials on the same key ring as the motorcycle key.

- Do not put any other ignition key with a transponder chip fitted near the motorcycle key when in use.

- Do not modify the immobiliser system.

- Do not submerge the key in water or any other fluid.

- Do not drop or strike the key against hard material.

Diagnostics

To fully diagnose the immobiliser system it is necessary to check for fault codes in the keyless ECM using the Triumph diagnostic tool (see System Diagnostics).

Further Diagnosis

The diagnostic trouble code tables, if used correctly, help to pinpoint a fault in the system once a diagnostic trouble code has been stored (see System Diagnosis - Keyless ECM).

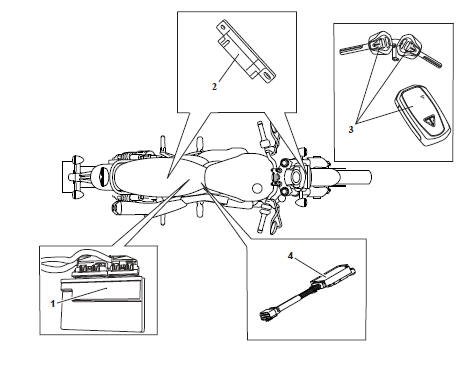

Immobiliser Components Location

- Engine ECM

- LF Antenna

- Transponder chip

- Keyless ECM

Engine Management Adaption

General Information

The engine management system fitted to this model is adaptive. This means that the system is able to learn about new or changing operating conditions and continuously adapt itself without needing to constantly make major adjustments from a fixed baseline setting.

Adaptive changes can become necessary because of changing rider behaviour, changes in the region in which the motorcycle is operated (i.e. operation at high altitude where it was previously used at sea level) or because a new part may have been fitted which has slightly different characteristics to the old part. All adaptive changes are automatic and require no intervention by rider or dealer.

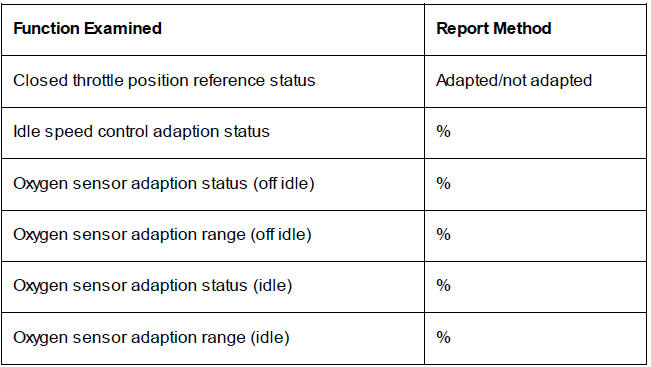

Adaption Status

To see if a motorcycle has fully adapted, a facility named 'ADAPTION STATUS' is provided on the diagnostic tool. The following adaption details can be examined:

Terminology

Where the term 'status' is used, this indicates how far the present operating parameter is from the stored (baseline) value. The nearer these figures are to zero the better as it indicates the motorcycle has adapted to its current operating conditions.

The term 'range' indicates how much (in percentage terms) of the adjustment range has been used to reach the current operating status.

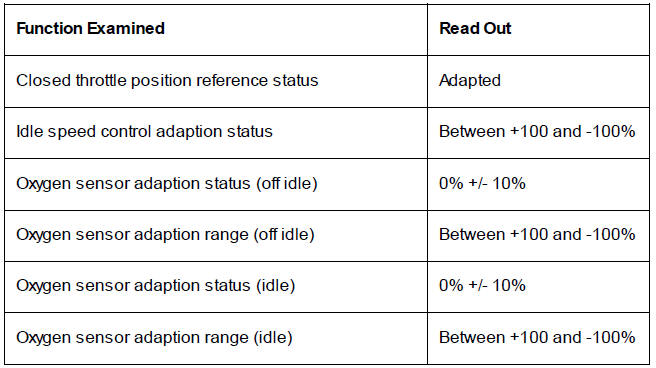

Typical Values

In a correctly adapted motorcycle, the following will be typical:

Forcing Adaption to Take Place

If the read out indicates that the motorcycle is not adapted, the following will force the system to make adaptions:

WARNING

Never start the engine or let it run for any length of time in a closed area. The exhaust fumes are poisonous and may cause loss of consciousness and death within a short time. Always operate the motorcycle in the open-air or in an area with adequate ventilation.

Note

Resetting adaptions with the motorcycle connected to an exhaust extraction system may cause incorrect values to be set, causing poor engine running.

Always reset the adaptions with the engine disconnected from any exhaust extraction system whilst ensuring the motorcycle is positioned in a well ventilated area.

1. Ensure 1. the engine is cold.

2. WITHOUT TOUCHING THE THROTTLE, start the engine and allow it to warm up until the cooling fan comes on.

3. Leave the engine to idle for a further 12 minutes.

Note

As an alternative to the above process, connect the diagnostic tool, select ADJUST TUNE (see the Triumph Diagnostic Tool User Guide) and select RESET ADAPTIONS. This will force a fast adaption routine to take place in around five seconds. For this to happen, the engine MUST be running, it must be at normal operating temperature and in closed loop control mode. Under any other conditions fast adaption will not take place and may cause default values to be loaded, which may then require a normal 12 minute adaption routine to be run.

Fault Indications

If 'range' figures at 100% are seen, then the adjustment has reached maximum indicating a mechanical fault exists on the motorcycle. This can be due to a number of faults but the most likely causes will be low/high fuel pressure, faulty injectors or air leaks at the throttle bodies or airbox.

In these circumstances, locate and rectify the fault, and reset the adaptions as described above.

See also:

Triumph Scrambler 1200 XC - Service manual > Engine Management System

Triumph Scrambler 1200 XC - Service manual > Engine Management System

System Description This model is fitted with an electronic engine management system which encompasses control of both ignition and fuel delivery. The engine electronic control module (ECM) draws information from sensors positioned around the engine, cooling and air intake systems and precisely calculates ignition advance and fueling requirements for all engine speeds and loads.

Ducati Scrambler

Ducati Scrambler Fantic Caballero 500

Fantic Caballero 500 Indian FTR 1200

Indian FTR 1200 Moto Guzzi V85 TT

Moto Guzzi V85 TT Royal Enfield Bullet Trials Works Replica

Royal Enfield Bullet Trials Works Replica Triumph Scrambler 1200 XE

Triumph Scrambler 1200 XE Triumph Street Scrambler

Triumph Street Scrambler Yamaha XSR700

Yamaha XSR700 Ducati Scrambler 800

Ducati Scrambler 800 Moto Guzzi V85 TT

Moto Guzzi V85 TT Triumph Scrambler 1200 XC

Triumph Scrambler 1200 XC