Ducati Scrambler 800 - Service manual > Refitting the flywheel/generator assembly

Ducati Scrambler 800 - Service manual > Refitting the flywheel/generator assembly

If previously disassembled, reassemble the flywheel following the indications described below.

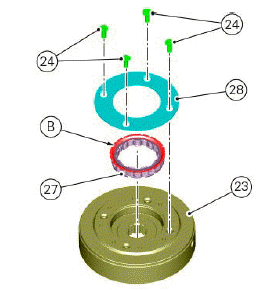

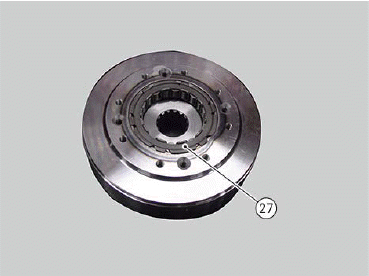

Fit starter clutch (27) on flywheel (23).

Bring the starter clutch edge (B) fully home on the flywheel.

Position flange (28) on the flywheel and start screws (24).

Tighten screws (24).

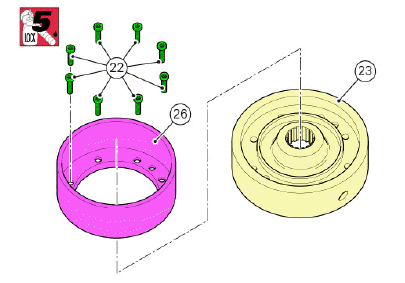

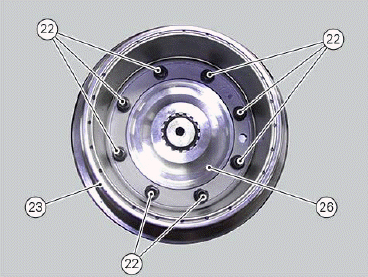

Position rotor (26) on flywheel (23).

Apply the indicated threadlocker and start screws (22).

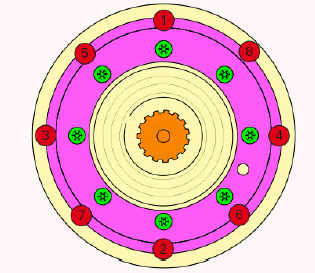

Tighten screws (22) respecting the indicated sequence to a torque of 13 Nm (Min 11 Nm Max 15 Nm).

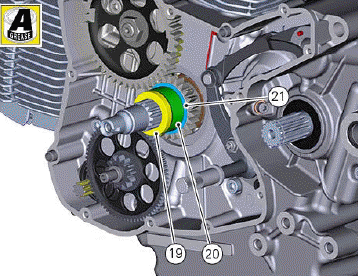

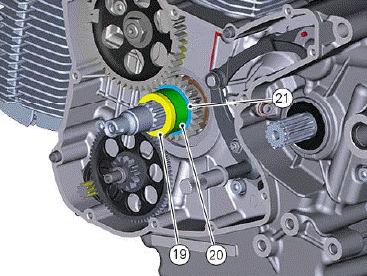

Fit on the crankshaft the washer (21), duly lubricated, roller bearing cage (20) and the internal ring (19) so that the latter is centred in the washer.

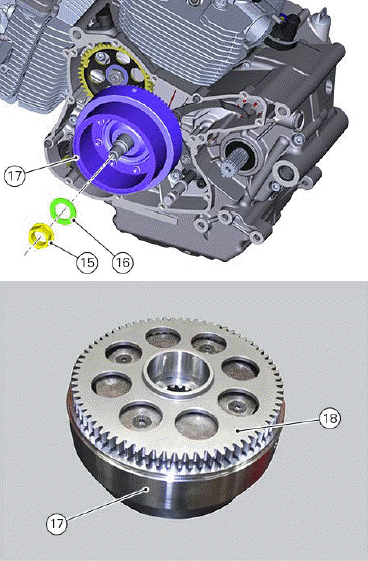

Install the flywheel-rotor-driven gear assembly on the crankshaft ensuring not to move the internal ring (19) in washer (21).

The flywheel assembly must be positioned with the reference sign aligned with the crankshaft groove, near the key seat.

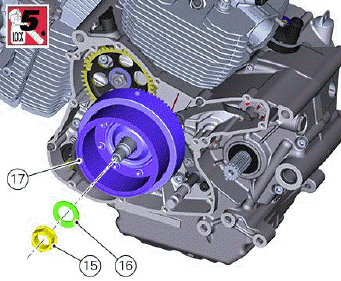

Use engine oil to lubricate the mating surfaces of the belleville washer (16).

Fit the belleville washer (16) on the end of the crankshaft.

Smear both crankshaft threading and flywheel nut one (15) with specified threadlocker.

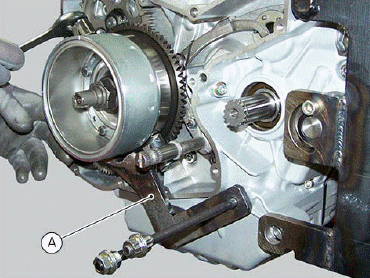

Block the flywheel rotation with the suitable tool (A) no. 88713.2036.

Tighten nut (15) to a torque of 270 Nm (Min. 256 Nm - Max. 284 Nm)

Overhauling the flywheel/generator assembly

Inspect the inner part of generator rotor (8) for signs of damage.

Check that the starter clutch is working properly and that the roller races do not show signs of wear or damage of any kind.

Disassemble the unit if you find faulty operation.

Removing the flywheel/generator assembly

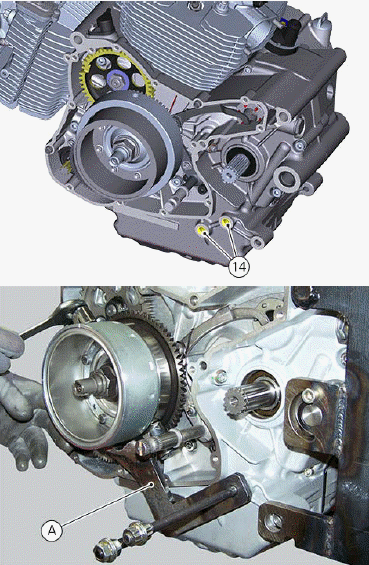

Fix tool (A) part no. 88713.2036 to the mounting holes (14) of side stand.

Secure the tool to the flywheel with the suitable screws.

Loosen nut (15) securing the generator flywheel by heating it up with an "industrial heating gun"; we recommend not to use naked-flame heating methods that could damage the starting components.

Warning While unscrewing the nut, apply axial pressure to the socket to avoid damage or injury in the event of the wrench suddenly slipping off the nut.

Remove nut (15), belleville washer (16) and the flywheel assembly (17) with gear (18).

Remove the inner ring (19), the needle roller bearing cage (20) and the washer (21).

Checking the flywheel/generator assembly

Inspect the inner part of generator rotor for signs of damage.

Check that the starter clutch is working properly and that the roller races do not show signs of wear or damage of any kind.

Disassemble the unit if you find faulty operation.

Disassembling the flywheel/generator assembly

Unscrew the eight screws (22) and remove the generator rotor (26) from the flywheel (23).

Working on the opposite side, loosen the four screws (24) and remove the flange (26).

Remove the starter clutch (27).

See also:

Ducati Scrambler 800 - Service manual > Refitting the generator cover

Ducati Scrambler 800 - Service manual > Refitting the generator cover

Remove any scale and grease from the mating surfaces of the left-hand crankcase half and the generator cover. Fit the two centring bushes (26).

Ducati Scrambler

Ducati Scrambler Fantic Caballero 500

Fantic Caballero 500 Indian FTR 1200

Indian FTR 1200 Moto Guzzi V85 TT

Moto Guzzi V85 TT Royal Enfield Bullet Trials Works Replica

Royal Enfield Bullet Trials Works Replica Triumph Scrambler 1200 XE

Triumph Scrambler 1200 XE Triumph Street Scrambler

Triumph Street Scrambler Yamaha XSR700

Yamaha XSR700 Ducati Scrambler 800

Ducati Scrambler 800 Moto Guzzi V85 TT

Moto Guzzi V85 TT Triumph Scrambler 1200 XC

Triumph Scrambler 1200 XC