Ducati Scrambler 800 - Service manual > Lubricating the chain

Ducati Scrambler 800 - Service manual > Lubricating the chain

O-ring chains have sealed, life-lubed link studs and bushes.

However, these chains need to be lubricated at regular intervals to protect metal parts of the chain and the O-rings.

Lubrication also serves to keep the O-rings soft and pliable to ensure the maximum sealing efficiency.

Using a brush, apply a thin protective layer of high-density gearbox oil along the entire length of the chain both inside and outside.

Washing the chain

Chains with O-rings must be washed in oil, diesel fuel or paraffin.

Do not use fuel, trichloroethylene or other solvents which will damage the rubber O-rings.

For the same reason use only sprays specifically formulated for use with O-ring chains.

Refitting the rear sprocket

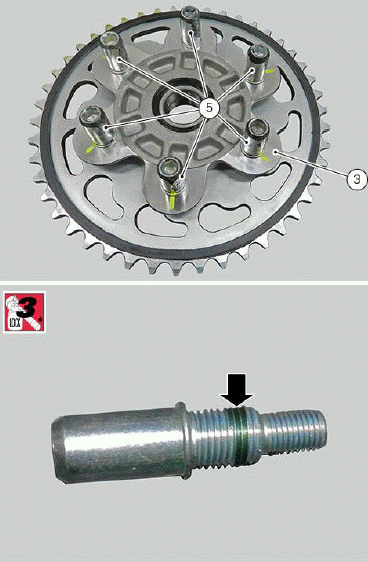

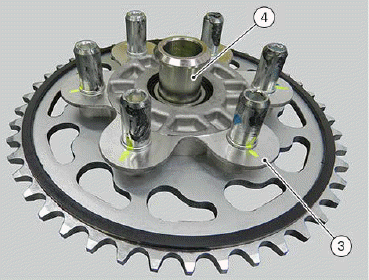

If removed, screw pins (5) to the rear sprocket flange (3) with specified threadlocker applied in the indicated point.

Tighten the pins to a torque of 46 Nm +- 5%.

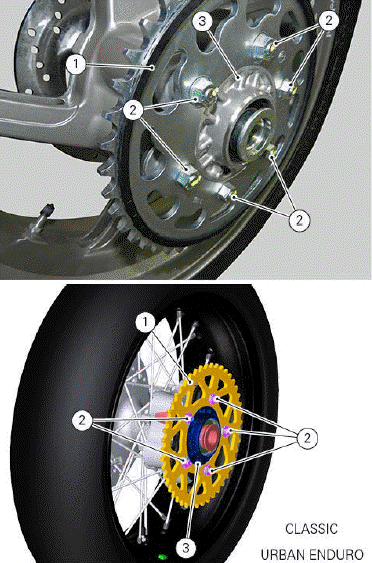

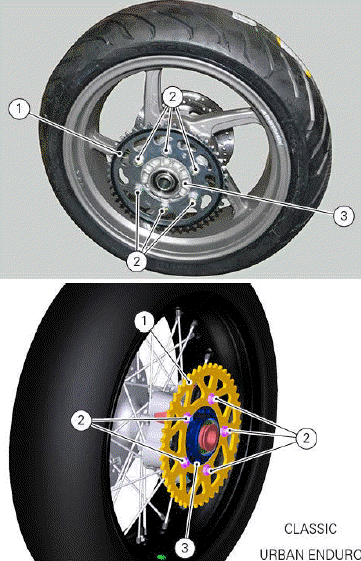

Position rear sprocket (1) on rear sprocket flange (3) and start nuts (2).

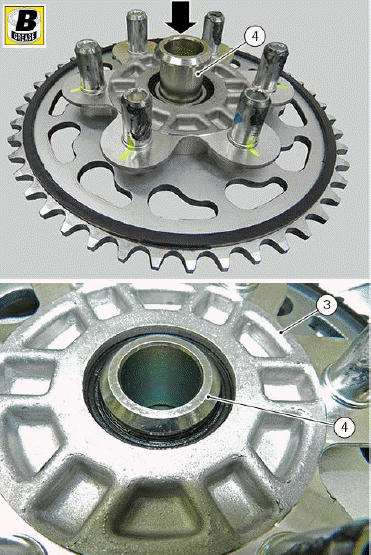

Insert spacer (4) fully home.

Lubricate the pins with the recommended product.

Position the rear sprocket flange-rear sprocket assembly in the rear wheel.

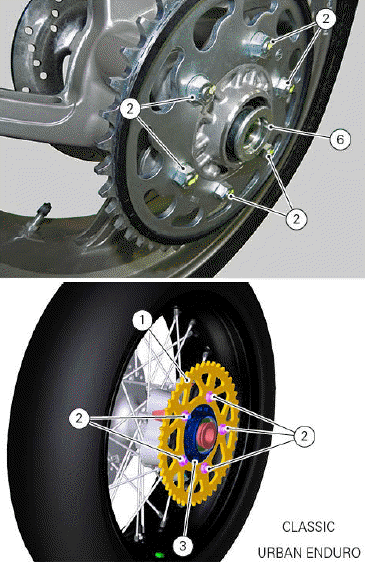

Fit spacer (6) and tighten nuts (2) to a torque of 46 Nm +- 5%.

Refit the rear wheel (Refitting the rear wheel).

Removing the rear sprocket

Remove the rear wheel (Removing the rear wheel).

Loosen nuts (2) retaining rear sprocket (1) to rear sprocket flange (3).

Remove the rear sprocket flange (3) from the rear wheel.

Remove spacer (4).

Loosen the nuts retaining the rear sprocket to the rear sprocket flange previously loosened.

See also:

Ducati Scrambler 800 - Service manual > Refitting the front sprocket

Ducati Scrambler 800 - Service manual > Refitting the front sprocket

Check that the splines of the gearbox secondary shaft and the sprocket are in perfect condition. Insert the sprocket on the gearbox secondary shaft and push it over the groove (7).

Ducati Scrambler

Ducati Scrambler Fantic Caballero 500

Fantic Caballero 500 Indian FTR 1200

Indian FTR 1200 Moto Guzzi V85 TT

Moto Guzzi V85 TT Royal Enfield Bullet Trials Works Replica

Royal Enfield Bullet Trials Works Replica Triumph Scrambler 1200 XE

Triumph Scrambler 1200 XE Triumph Street Scrambler

Triumph Street Scrambler Yamaha XSR700

Yamaha XSR700 Ducati Scrambler 800

Ducati Scrambler 800 Moto Guzzi V85 TT

Moto Guzzi V85 TT Triumph Scrambler 1200 XC

Triumph Scrambler 1200 XC