Ducati Scrambler 800 - Service manual > Changing the front phonic wheel sensor

Ducati Scrambler 800 - Service manual > Changing the front phonic wheel sensor

REMOVAL PROCEDURE

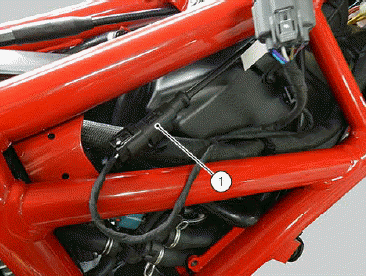

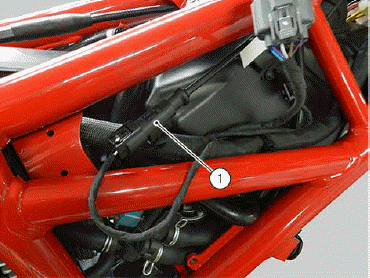

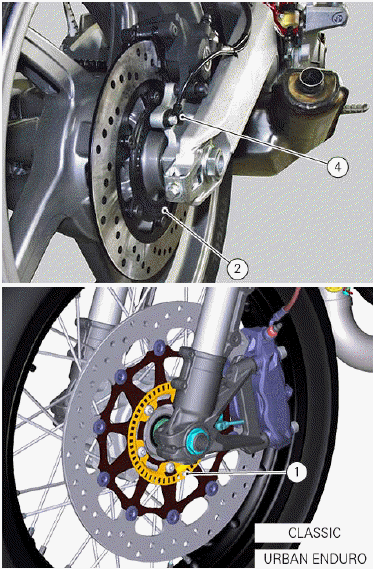

Disconnect front ABS sensor (2) connector (1) from main wiring.

Open all clips retaining front ABS sensor cable (1): refer to tables under Section: "Routing wiring harnesses / hoses".

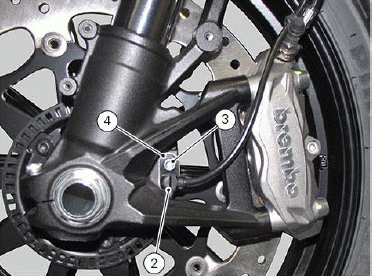

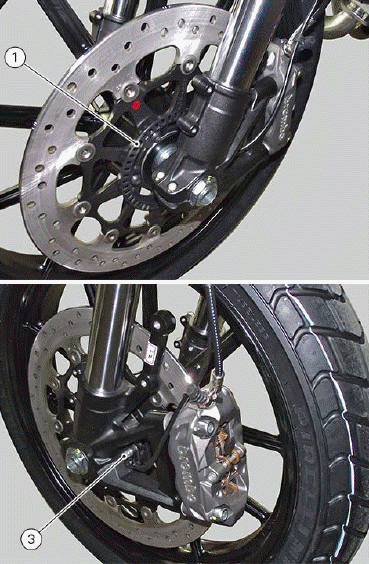

Undo the retaining screw (3), and remove front ABS sensor (2) with calibrated gasket (4), sliding cable out from cable grommet.

REFITTING PROCEDURE

Before refitting, make sure that contact parts between front ABS sensor (2) and its seat are free of damage and perfectly clean. Fit the new front ABS sensor (2) on its seat inserting the screw (3). Check air gap between front ABS sensor (2) and front phonic wheel as explained under Section "Adjusting the AIR-GAP of phonic wheel sensor".

Tighten screw (3) to a torque of 7 Nm +-10%.

Connect connector (1) to main wiring. Fasten all clips retaining front ABS sensor cable (1): refer to tables under section "Routing wiring harnesses / hoses".

ABS component maintenance

Bleeding of the ABS hydraulic system

If brake controls feel "spongy" due to the presence of air bubbles in the system, bleed as usual, as described in Section (Changing the front brake system fluid) and (Changing the rear brake system fluid).

Before bleeding a brake master cylinder, move back the calliper pistons to let any air build-up in the ABS control unit flow into the master cylinder.

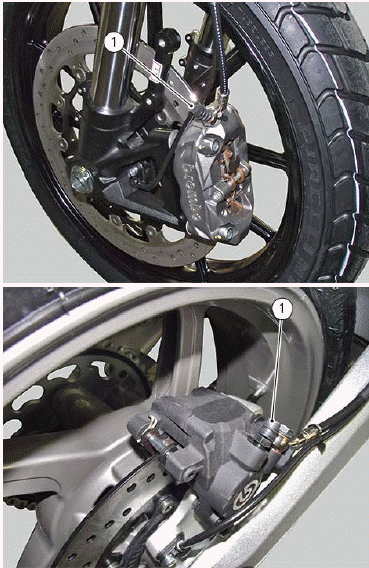

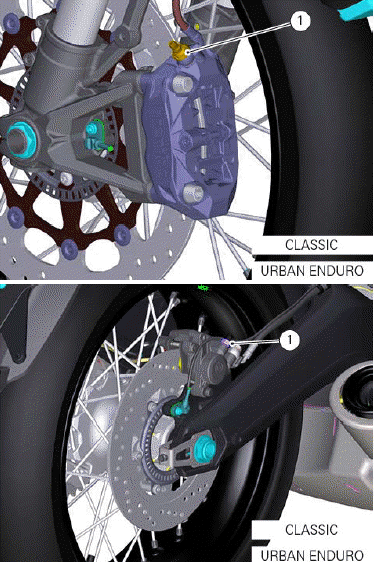

Purge must be carried out by means of the corresponding unions (1) placed on the callipers and the brake master cylinders.

Important Do not undo the special screws securing the pipe unions on the ABS hydraulic control unit, unless control unit replacement is necessary.

Important If the ABS hydraulic control unit has been replaced, it will be supplied with the secondary circuit already filled with fluid. Control unit must thus be assembled and the system filled and drained as a traditional system.

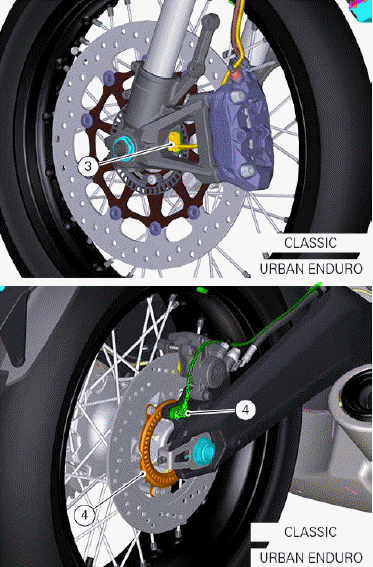

Adjusting the AIR-GAP of phonic wheel sensor

(For front as well as rear sensor) In each case of maintenance that foresees:

- replacing or refitting the wheel;

- replacing or refitting phonic wheel (1) or (2);

- replacing or refitting the brake discs;

- replacing or refitting the speed sensor (3) or (4);

- (front) replacing or refitting the sensor holder bracket;

- (rear) replacing or refitting of the calliper holder plate.

It is necessary to check the air-gap between the speed sensor and the phonic wheel, once the components are refitted.

Note Perform the test in three points of the phonic wheel, at a distance of 120Вє one from the other.

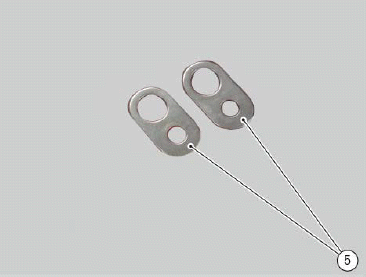

To do this, use two feeler gauges (5) of 0.2 mm and 0.5 m.

AIR-GAP adjustment procedure

Between front phonic wheel (1) and front ABS sensor (3), and between rear phonic wheel (2) and rear ABS sensor (4) there must be an air-gap between 1.3 mm and 1.9 mm.

To check it, use a suitable feeler gauge.

Tighten the sensor securing screw fully home every time you add or remove a shim.

Measure the AIR-GAP.

Put the required shims.

Important The sum of the feeler gauge must never exceed 3 mm.

Once the shimming is completed, tighten the sensor retaining screw to a torque of 7 Nm +- 10% and check the AIR-GAP again.

See also:

Ducati Scrambler 800 - Service manual > Handlebar assembly

Ducati Scrambler 800 - Service manual > Handlebar assembly

Handlebar assembly: throttle control Refitting the throttle control Fit throttle control on handlebar. Fasten the handlebar as described in chapter "Refitting the handlebar".

Ducati Scrambler

Ducati Scrambler Fantic Caballero 500

Fantic Caballero 500 Indian FTR 1200

Indian FTR 1200 Moto Guzzi V85 TT

Moto Guzzi V85 TT Royal Enfield Bullet Trials Works Replica

Royal Enfield Bullet Trials Works Replica Triumph Scrambler 1200 XE

Triumph Scrambler 1200 XE Triumph Street Scrambler

Triumph Street Scrambler Yamaha XSR700

Yamaha XSR700 Ducati Scrambler 800

Ducati Scrambler 800 Moto Guzzi V85 TT

Moto Guzzi V85 TT Triumph Scrambler 1200 XC

Triumph Scrambler 1200 XC