Ducati Scrambler 800 - Service manual > Changing the timing belts

Ducati Scrambler 800 - Service manual > Changing the timing belts

Remove the exhaust system (Removing the exhaust system).

Remove the belt covers (Removing the timing belt external covers).

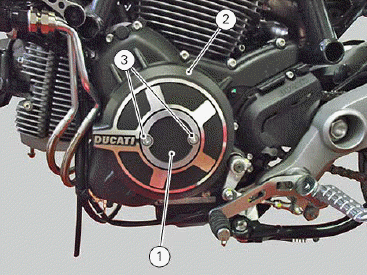

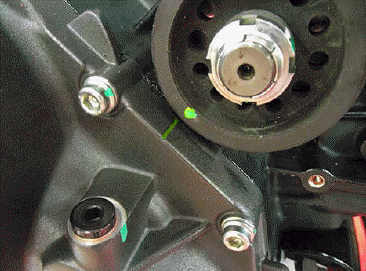

Working from vehicle left-hand side, loosen the two screws (3) and remove plug (1) from generator cover (2) .

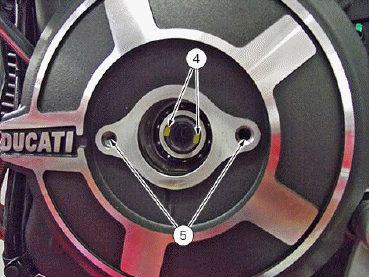

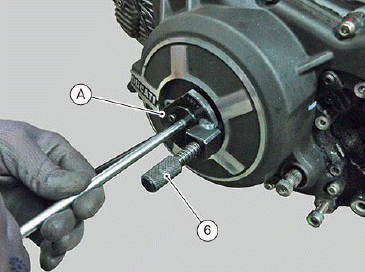

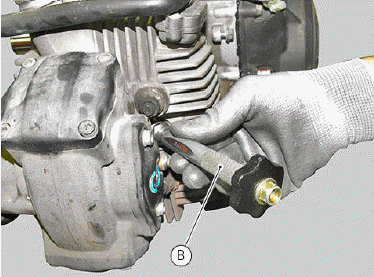

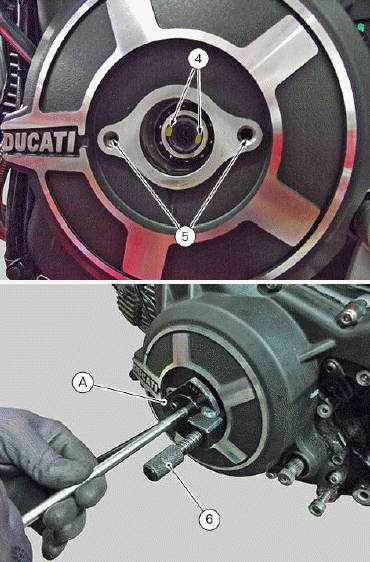

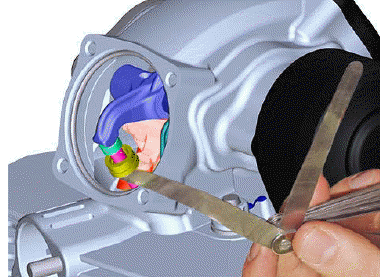

Fit tool (A) part no. 88713.2011 so that pins inside the tool engage into the two notches (4) on generator cover.

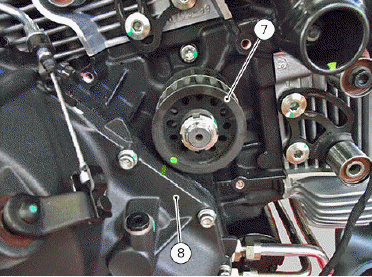

Working on the opposite side, align the reference mark on belt roller (7) with the reference mark on crankcase (8) turning tool (A).

This condition is the TDC in the combustion stage with the horizontal cylinder.

Check it by inserting tool (B) in the spark plug hole.

Now tool (A) pin (6) should be aligned with one of the two holes (5) on generator casing.

Tighten pin (6) so as to lock out tool (A) rotation.

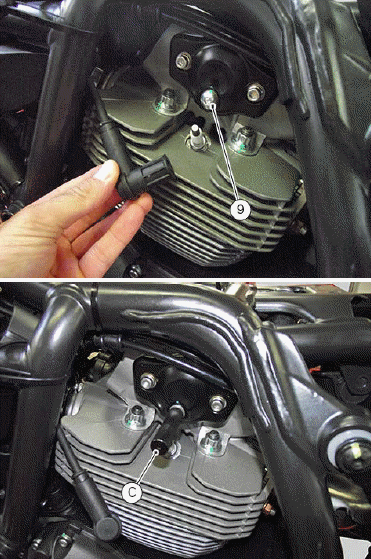

Work on the vertical head and remove spark plug cap and plug (9).

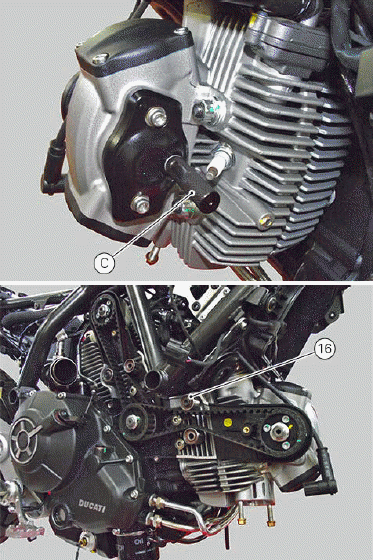

Fit tool (C) part no. 88713.2288 fully home.

If that is not possible, turn belt roller (7) until tool (C) can be inserted fully home.

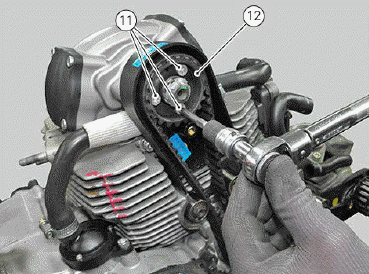

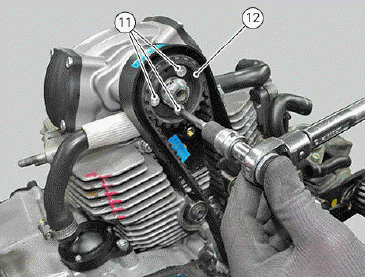

Loosen screws (11) of pulley (12) - vertical and horizontal cylinder.

Turn pulley counter clockwise.

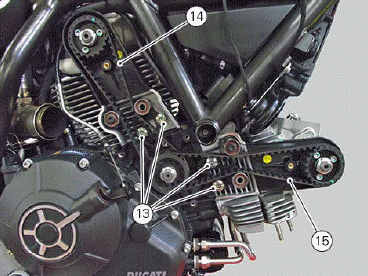

Loosen the two screws (13) from belt tensioner (14) on vertical cylinder and belt tensioner (15) on horizontal cylinder.

Remove both belts.

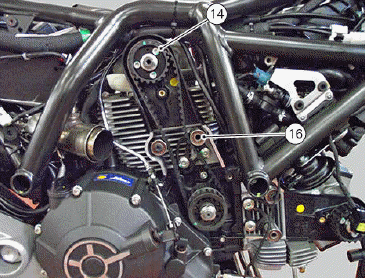

Fit belt (14) and tension it by hand using the mobile belt tensioner (16).

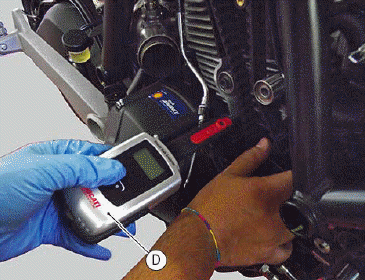

Check proper tensioning using the suitable tool (D) part no. 97900.0253, frequency reading for proper tensioning is 140 Hz with a new belt.

If this value is not reached, work the mobile tensioner (16) until getting the proper reading.

Tighten screws (11) of pulley (12).

Remove tool (C), tighten the plug and put back spark plug cap.

Apply the same procedure to the horizontal head.

Refit the belt covers (Refitting the timing belt external covers).

Refit the exhaust system (Refitting the exhaust system).

Checking valve clearance

Remove the seat (Removing the seat).

Remove the fuel tank (Removing the fuel tank).

Remove the blow-by (Removing the airbox).

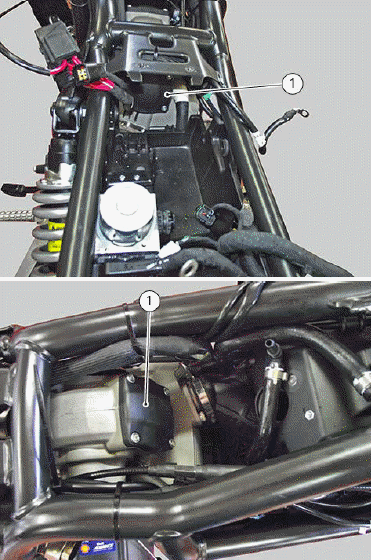

Remove the following parts from the electrical component box:

- Battery;

- Starter relay;

- Fuse box;

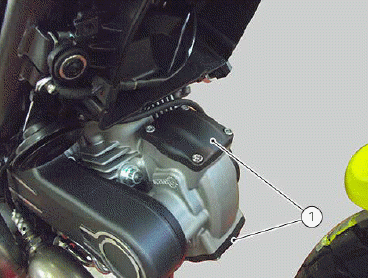

Remove the cylinder head covers (1).

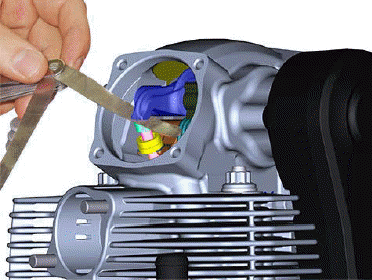

Fit tool part no. 88713.011 and ensure the two tool pins match the two slots on crankcase following the same procedure as for "Changing the belts". Turn the crankshaft so that the valve to be inspected is in rest position.

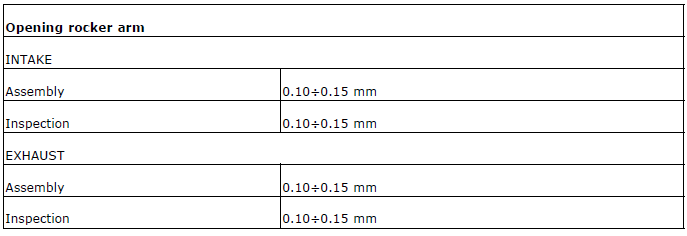

With the valve in the rest position, slide a feeler gauge between opening rocker arm and shim to measure the clearance. The clearance must be within the specified limits:

Opening rocker arm

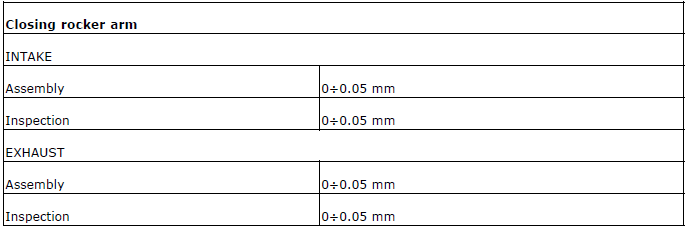

With the valve in the rest position, slide a feeler gauge between closing rocker arm and shim to measure the clearance.

Closing rocker arm

If detected values exceed the specified limits, replace opening and/or closing shims, as described in paragraph "Removing the valves and rocker arms", with one featuring an adequate thickness to obtain the specified clearance.

Note Opening rocker arm shims measuring from 1.8 to 3.45 and closing rocker arm shims from 2.2 to 4.5 are available as spare parts: the size is punched on the shim.

Reassemble the removed components in the removal reverse order.

See also:

Ducati Scrambler 800 - Service manual > Changing the fluid in the rear brake circuit

Ducati Scrambler 800 - Service manual > Changing the fluid in the rear brake circuit

Changing the fluid in the rear brake circuit Unscrew the cover (6) of the rear brake fluid reservoir (7).

Ducati Scrambler 800 - Service manual > Changing the engine oil and filter cartridge

Ducati Scrambler 800 - Service manual > Changing the engine oil and filter cartridge

Engine oil Note This operation has to be carried out with hot engine (but turned off) because the oil in these conditions is more fluid and comes out faster and completely.

Ducati Scrambler

Ducati Scrambler Fantic Caballero 500

Fantic Caballero 500 Indian FTR 1200

Indian FTR 1200 Moto Guzzi V85 TT

Moto Guzzi V85 TT Royal Enfield Bullet Trials Works Replica

Royal Enfield Bullet Trials Works Replica Triumph Scrambler 1200 XE

Triumph Scrambler 1200 XE Triumph Street Scrambler

Triumph Street Scrambler Yamaha XSR700

Yamaha XSR700 Ducati Scrambler 800

Ducati Scrambler 800 Moto Guzzi V85 TT

Moto Guzzi V85 TT Triumph Scrambler 1200 XC

Triumph Scrambler 1200 XC